Silver Cans

components are designed, Material Selected and Manufactured in All size and diameters following also specification. Castor wheels of fluff proof design patented by the company are the integral parts of pure state-of-the artisans.

The can body is made of a special blend of polymers- HDPE with plasticizer polymer blends, for making the butt weld perfect and stress-free. The butt welding is performed in a numerically controlled welding machine specially designed and also the weld area diffusion at the joint. Thus, a seamless barrel is made and joints are tested for impact resistance. The side seams of our cans have never failed at the joint, even after several years of intensive use in spinning.

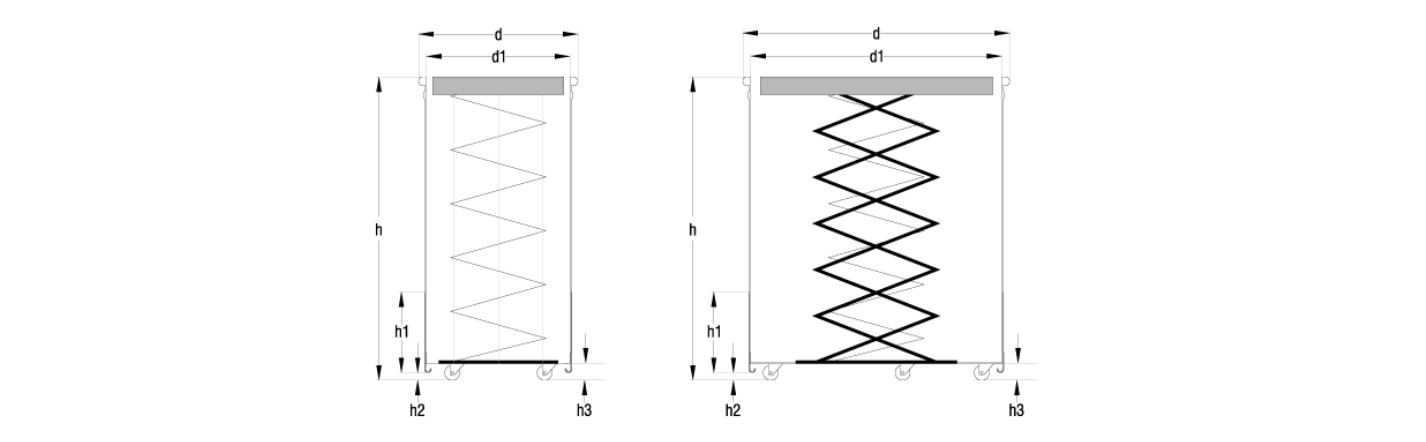

Spring with Pantograph and Plastic Top

(uptp 24″Dia) or GI Top (28″to40″Dia)

Spring for higher load and diameter of laid-on-sliver are fitted with pantograph. A triangular bottom is required for the free movement of the pantograph, so that the spring collapses uniformly.

The bottom of the pantograph is especially designed to accommodate the collapsed convoluted which ensure uniform movement of the sliver, not allowing any tilting of the top plate.

Box type spring

Spring are the heart of spinning cans. It is made of high carbon spring steel wirw. They are hear treat treated to ensure fatigure-free performance, uniform collapsibillity and realease, these are the quility spring of PUJACANS for fitment in modern spinning machines.

Plastic bottom covers are so designed that they allow clustering of coils of the spring withing themselves. This allow additional capicity for thee sliver to fill in.